The market-leading wire EDM CAM integrated in the leading CAD SolidWorks

Use the best CAM solution together with your preferred CAD system

The excellent Fikus CAM solutions for wire EDM completely integrated in the SolidWorks environment. Carry out all your CAD activities in the recognized SolidWorks software and, immediately, start all the CAM processes in the intuitive, flexible, efficient and proven Fikus CAM solution for wire EDM.

Innovative solution with advanced functions

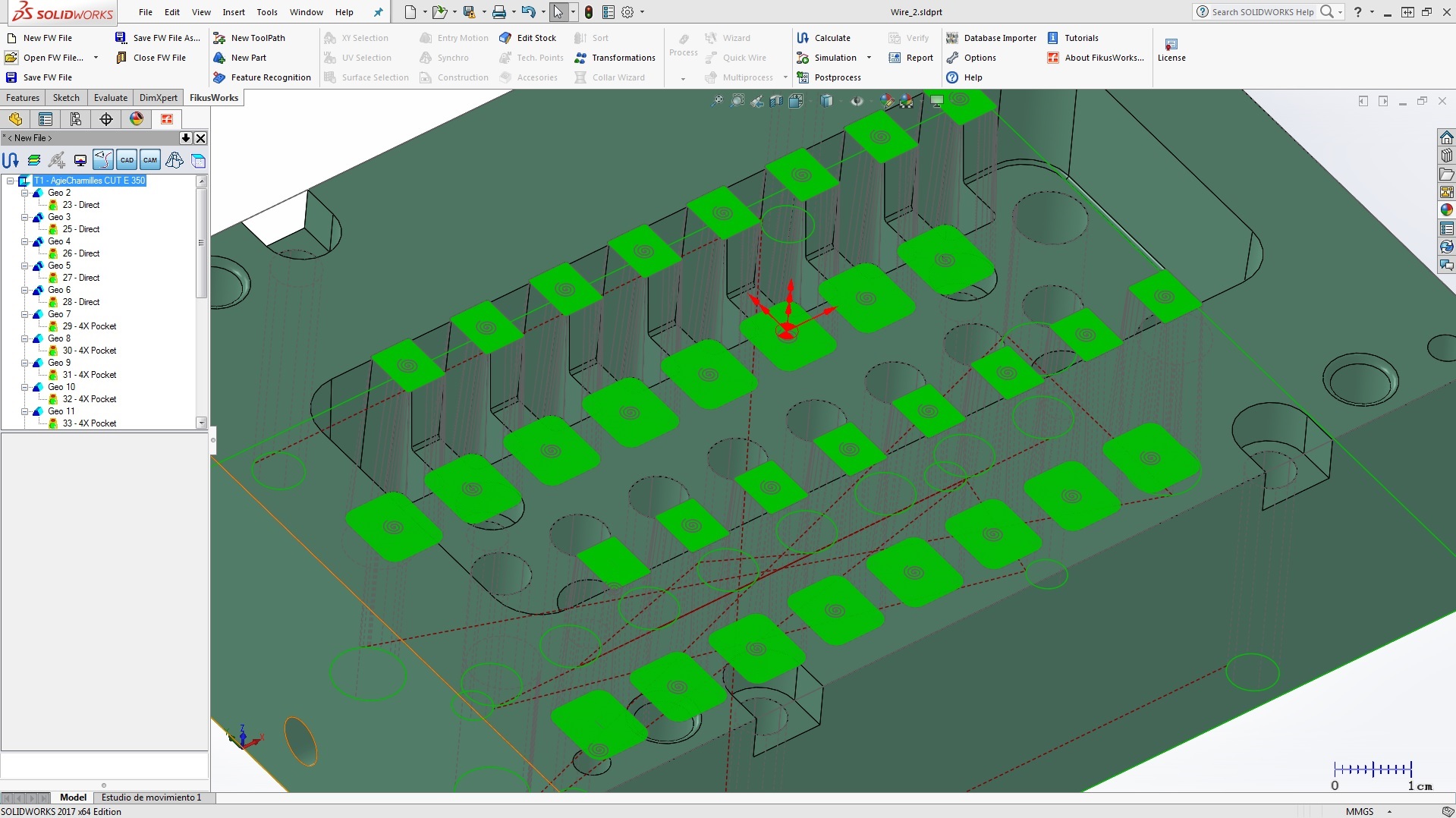

FikusWorks allows to program machining in 2 and 4 axes, including pockets. Fikus can also perform rotary axis processes, such as the Spin & Burn function.

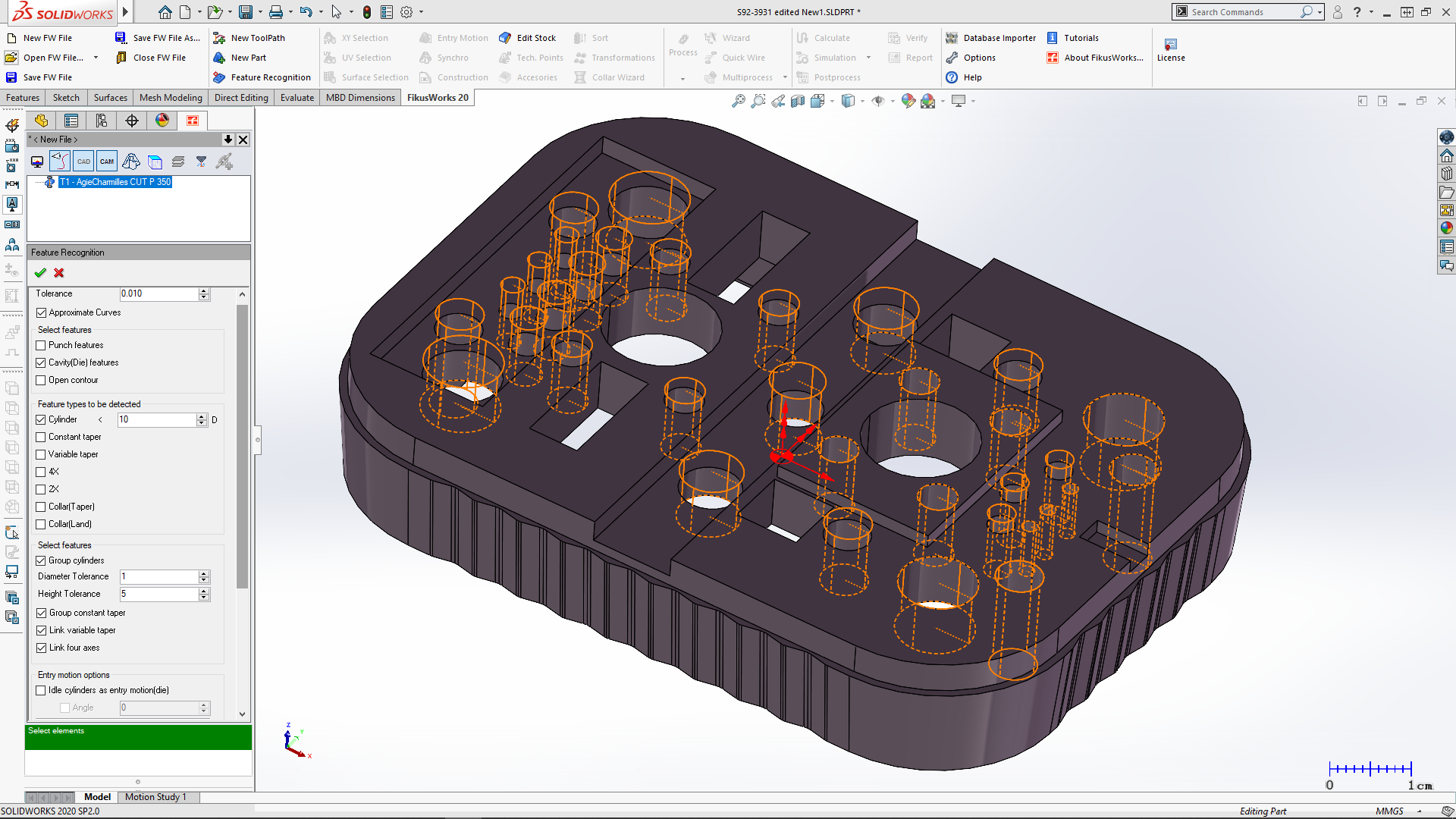

With FikusWorks a high degree of automation is possible thanks to the Feature Recognition function that recognizes all the characteristics of the elements to be machined. Even the threading of the wire is automatic.

Another outstanding feature is Auto-fix, which allows the workpiece to be easily removed with just a single stroke.

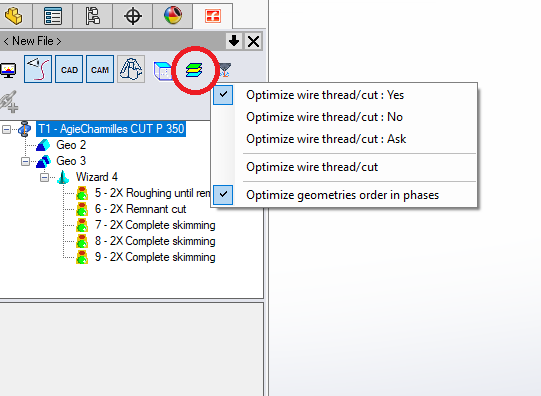

FikusWorks includes a multitude of functions, such as the new interface for cutting and threading.

FikusWorks Main Features

- Fully integrated in SolidWorks.

- Reduce time-to-market and working time drastically.

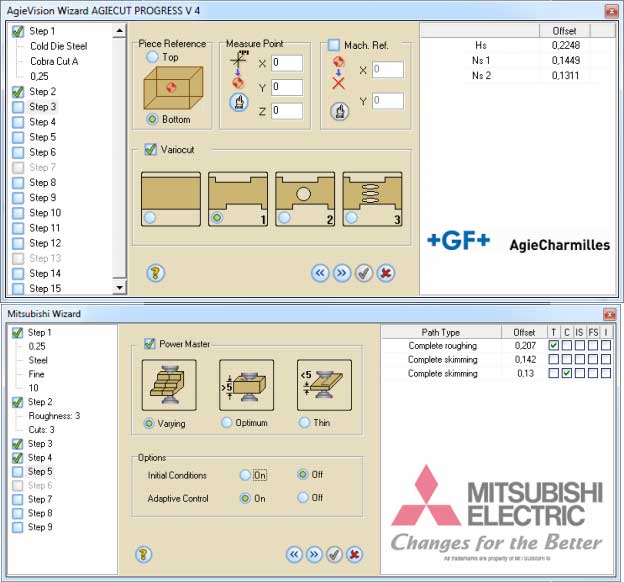

- Program all your wire EDM machines using the machine specific Wizard and technologic databases.

- Complete your job easily and safely guided by the efficient FikusWorks step-by-step assistant.

- Take advantage of the most advanced wire path calculation algorithms for 2X to 4X cuts.

- Enjoy the first commercial solution for 4X no-core-cuts.

Automatically selecting and grouping cylinders

Promotion

Free eBook

Discover how to take full advantage

of your wire EDM machine

using a dedicated CAM software

Download here

Expert knowledge of the wire EDM technology

FikusWorks is leading innovation in CAD/CAM for wire EDM machining because of its acknowledged expertise in controlling this extremely accurate and sophisticated technology. Our close work with the technology leaders put FikusWorks ahead of other CAM packages when it comes to get the most out of your wire EDM machine.

With FikusWorks you can machine any contoured mold, die, core, cavity shape or profile. Control every cutting parameter: offsetting, automatic threading, position of the wire, constant and variable taper, and our latest improvement: Auto-fix, control of the remnant size for a better part disengage.

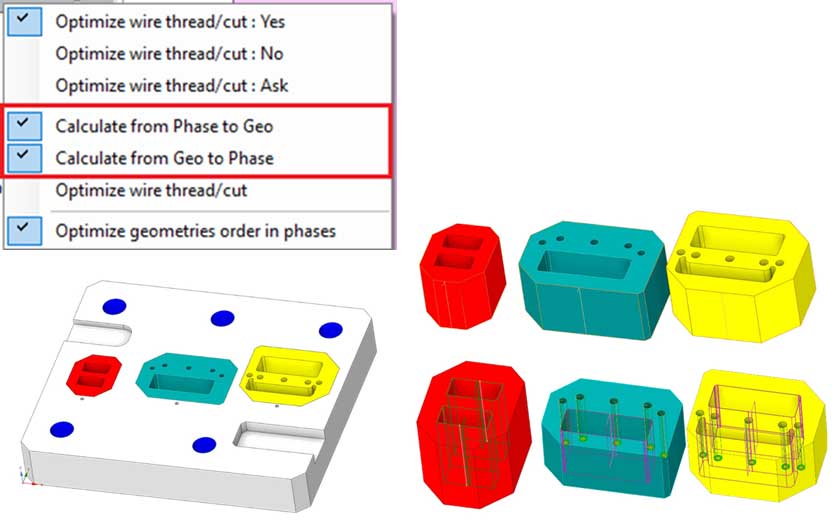

The Phases to Geo & Geo to Phases function (day/night option) allows maximum flexibility to organize machining processes helping to increase productivity by freely managing which processes will be performed without the need for operators to be present.

The deep knowledge of this technology and the inclusion of specific technological tables and post-processors for most of the machines on the market, allows Fikus to provide ultra-precise machining with the best surface quality.

Permanently updated

Thanks to FikusCloud online services, FikusWorks keeps postprocessors and technology boards permanently updated: updates to your wire machines will be immediately supported by your FikusWorks solution.

The Phases to Geo & Geo to Phases function (day/night option) allows you to decide which processes will be performed without operators being present

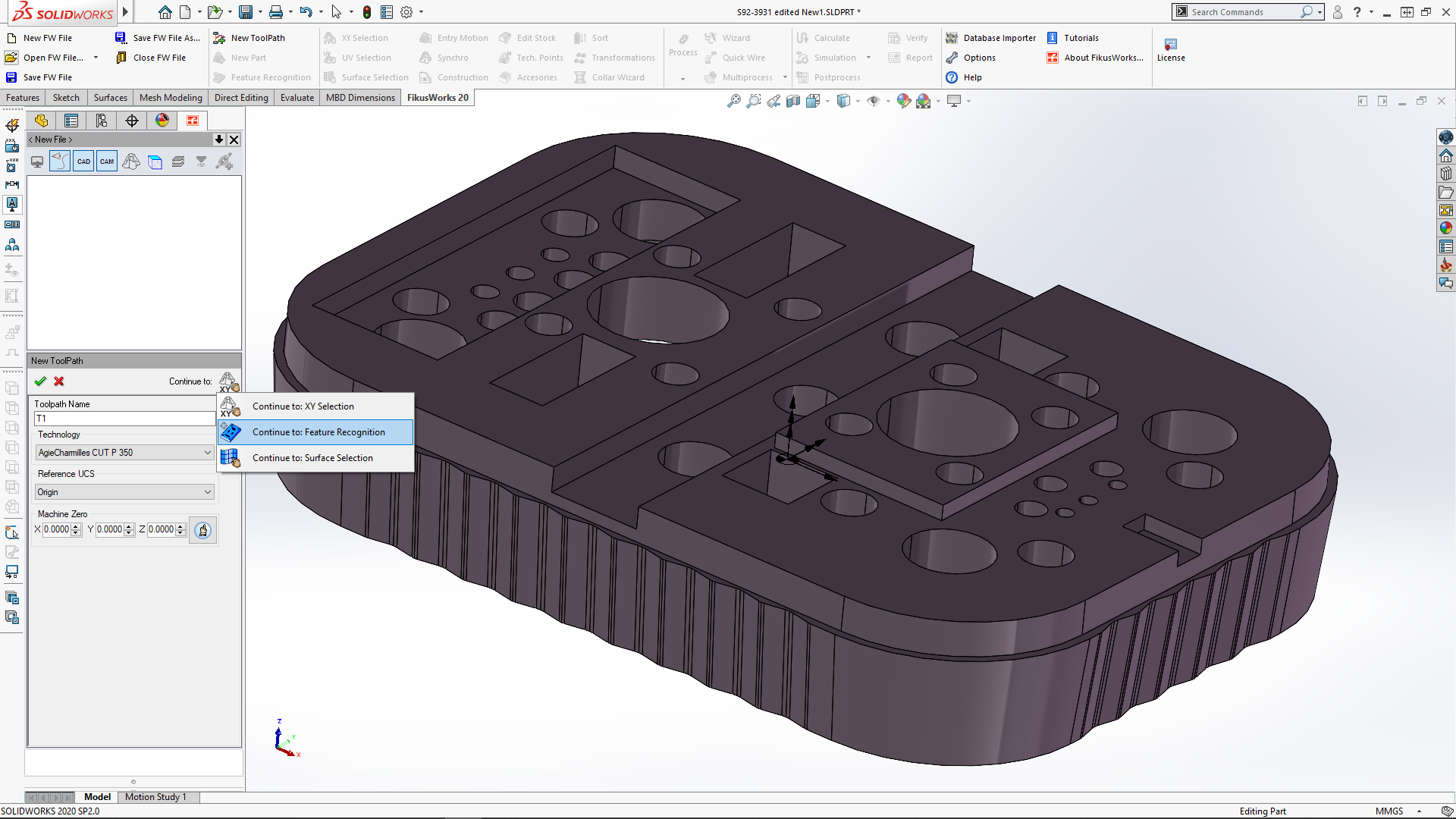

Optimal CNC programs in just three steps

Our engineers have developed FikusWorks with the goal of reducing the steps users must take to program a part. With each new release, FikusWorks simplifies programming in this complex technology until it becomes fully automatic.

FikusWorks is very easy to use and learn, and highly automated. It is only necessary to select the geometry, processes or parameters, and calculate.

The CAM manager, which guides the user from the definition of the part to be cut to the creation, calculation and simulation of each cutting process, generates the most efficient machining.

The Automatic Feature Recognition function detects detects all of the feature types to be cut on a part with just a couple of mouse clicks.

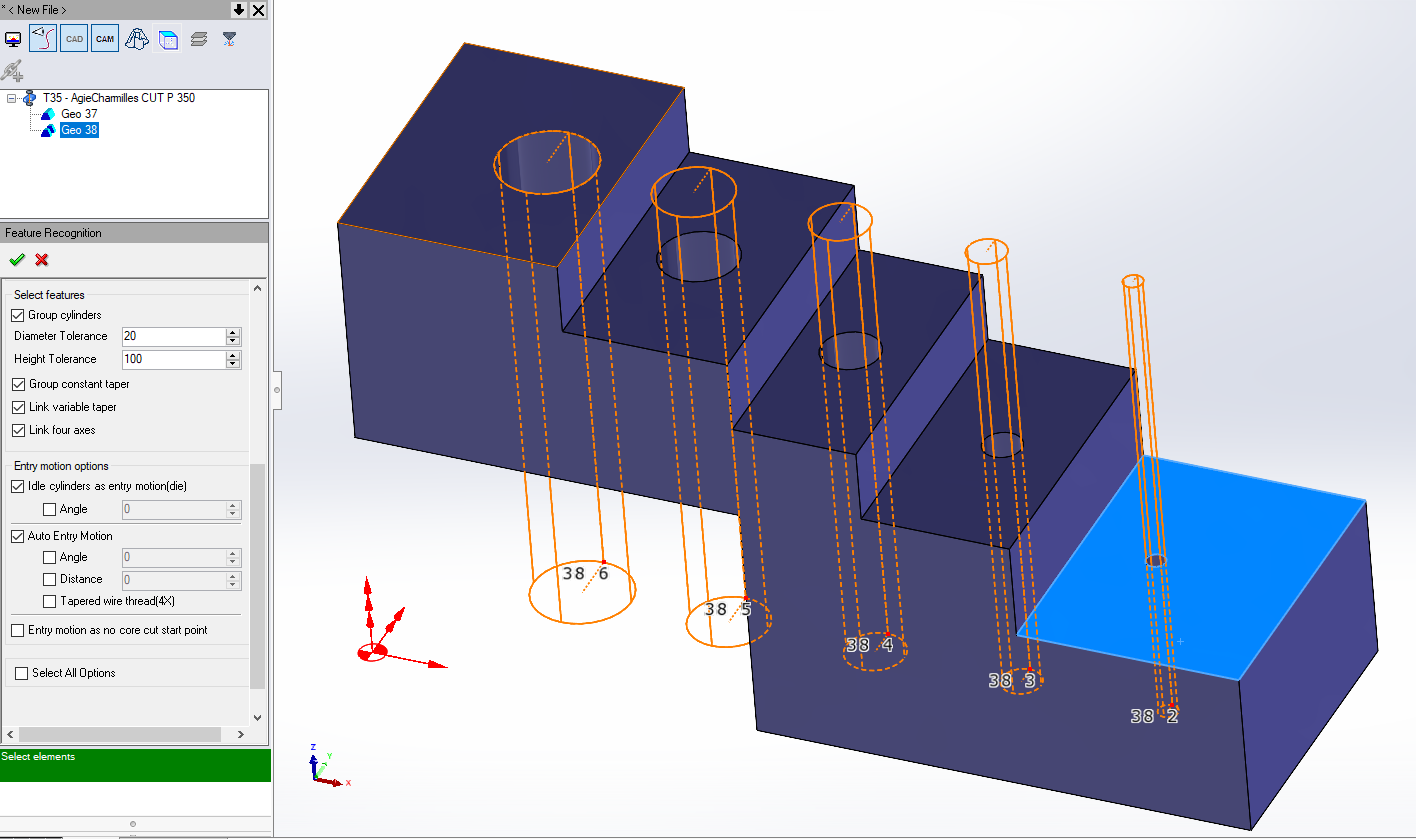

The Drill Wizard detects all drills, grouping them according to their features, and automatically and efficiently programs their machining.

Customizable templates allow you to save proven cutting strategies for future use on similar parts, saving time and avoiding errors.

Versatile drill grouping

Get the most out of your machines

Because not all machines work in the same way

FikusWorks has specific technological developments for each machine, because not all machines work in the same way. Our engineers have developed machine-specific technological assistants and postprocessors to allow FikusWorks users to prepare their machining in just seconds, easily and without errors. The post processors will generate an optimal cutting strategy for each machine and job type.

FikusWorks enables users to leverage the full capabilities of their machine investment to be competitive in a global market from the very first minute

FikusWorks includes cutting conditions databases from machines of the main machine makers, new and old, allowing you to generate programs automatically and easily, regardless of your machines.

Machine-specific technological developments

Only one program to work with all your machines

With FikusWorks you don't need to be an expert in the technology of all machines. FikusWorks is able to program them all.

SolidWorks 3D CAD Solution

At FikusWorks, CAD is provided by SolidWorks, the most recognized CAD developer, with effective solutions for any design need:

- SolidWorks 3D CAD

- Design Reuse and Automation

- Interference Check

- Part and Assembly Modelling

- CAD Library

- Design Analysis

- 2D Drawing

- 3D Animations and Photorealistic Renderings

- Design for Cost: Manufacturing Cost Estimation and Quoting

- CAD File Conversion

- Product Collaboration

- Design Manufacturability

SolidWorks environment

FikusWorks: A complete solution for wire EDM, or an add-in for your Solidworks CAD

Complete solution

FikusWorks is available as a comprehensive CAD/CAM solution, in three different configurations to suit your needs:

- SolidWorks CAD (parts-only) + Wire EDM CAM

- SolidWorks CAD (Parts & Assembly) + Wire EDM CAM

- SolidWorks CAD (Parts & Assembly & Drawings) + Wire EDM CAM

Fully integrated add-in

FikusWorks is also available as an add-in to integrate the best wire EDM CAM solution on the market into your Solidworks platform and start programming the machining immediately.

Once you have finished your CAD tasks, you can directly open the FikusWorks tab in the SolidWorks main menu and start working with the intuitive, easy to use and efficient Fikus CAM solution for wire EDM.

FikusWorks a comprehensive wire EDM solution or add-in for your Solidworks CAD

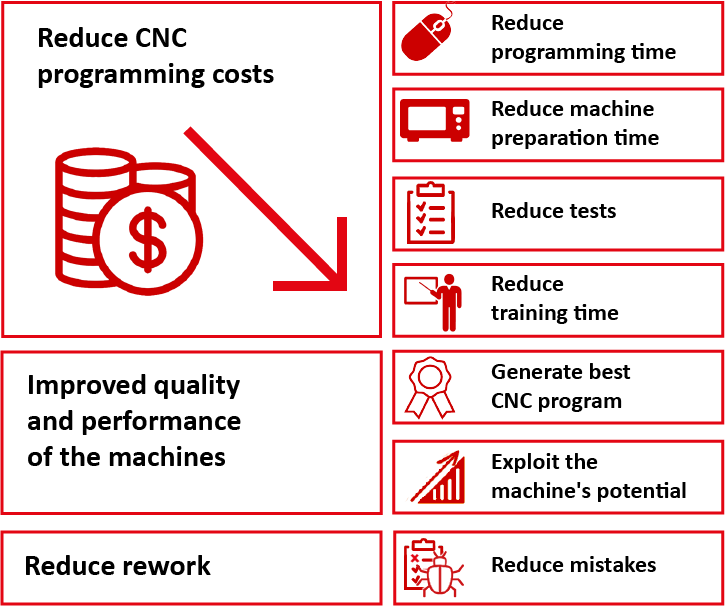

All advantages at FikusWorks for wire EDM

Fikus allows the user take full profit fron his investment in wire EDM machines to become competitive in a global market from the first minute.

It reduce the CNC programming costs due to its ability to reduce programming and preparation time in machine, the needed tests or training time.

Fikus allows to obtain the best quality and performance from the machines and reduces the risk of errors.

Advantages of FikusWorks for Wire EDM

Download here the PDF brochure

Click here or on the image to read, download or print the PDF file of our brochure.

Click here to access the brochures of all our products.

The best CAM, which optimizes the performance of your machines, together with your preferred CAD system

The best CAM, which optimizes the performance of your machines, together with your preferred CAD system