The destructive method in wire EDM

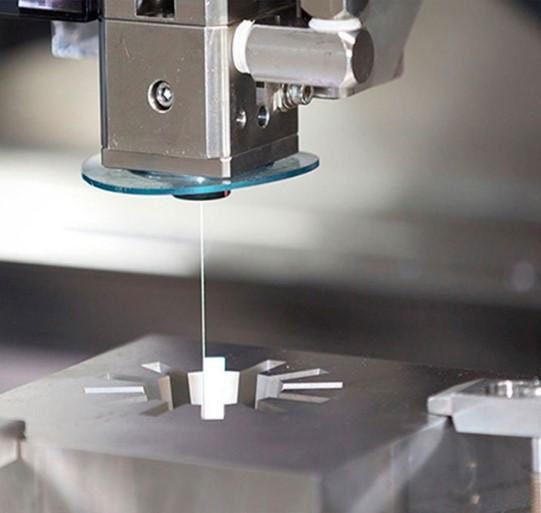

We know that Wire EDM is a machining process using a controlled electric arc, which removes the material by electrical discharges between an electrode (work tool) and the part to be machined and always in a dielectric medium.

It must be said that, in the case of wire EDM, the hardness of the material does not matter, what matters are the thermal and electrical characteristics of the material to be worked. For this reason, it is worth noting the great suitability for machining steels and hard alloys that are not very suitable for machining with metal removal machining methods.

Within the world of EDM in general there are several cutting methods: EDM cutting, Destructive or erosion by penetration, among others.

What is the destructive method in wire EDM?

The destructive method is a cutting process in which the wire will start from a threading point that may or may not be in the geometric center of the figure and will trace a path creating the final shape of the part without leaving any material uneroded.

Destructive process in wire EDM

When is the destructive method used?

There are three scenarios in which it is necessary to use the destructive method:

- In very small machining operations, when with a conventional cut we cannot secure the piece of remnant due to lack of space.

- In parts whose geometry makes it impossible for the remnant to fall downwards and we are not interested in stopping the machine to remove the remnant.

- Simply, in shapes that require this type of machining due to their geometry.

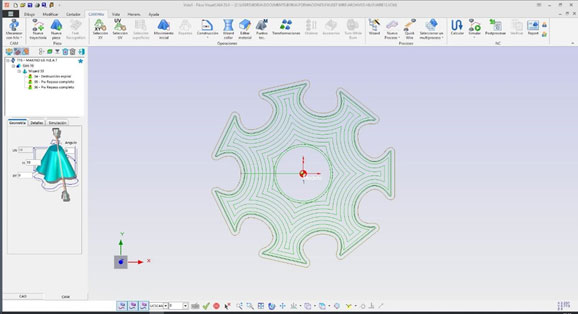

Tool paths in wire EDM destructive machining

How does the destructive method work?

We have already mentioned that the destructive leaves no core in the cut, but how does it do this? In our case, Fikus Visualcam generates a continuous path that, from the threading hole, is gradually adjusted to the outer contour respecting a constant percentage of wire overlap in each pass. These paths can be generated in both 2x and 4x which gives us the possibility to machine many types of geometries.

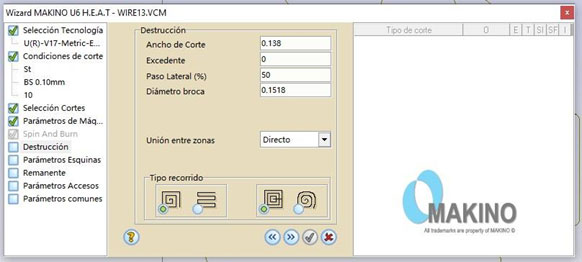

Fikus Visualcam Wire EDM solutions are equipped with the Wizard tool, which includes the machine technology and has the possibility to choose different types of machining paths. In addition, we can define the cutting width, the overlap for a reworking pass and the overlap step in percent for the wire.

Machining assistant with machine-specific technology