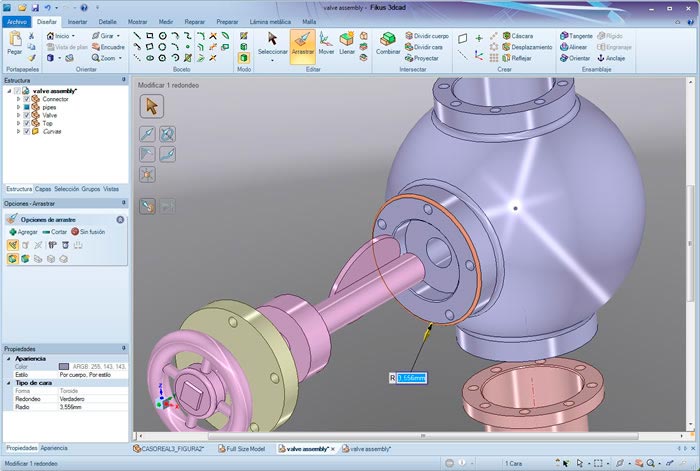

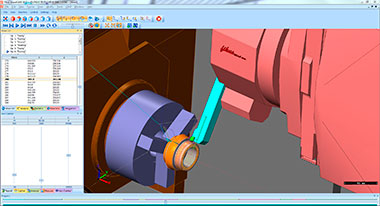

Fikus Visualcam 18 Improvements

A step foward in usability and productivity

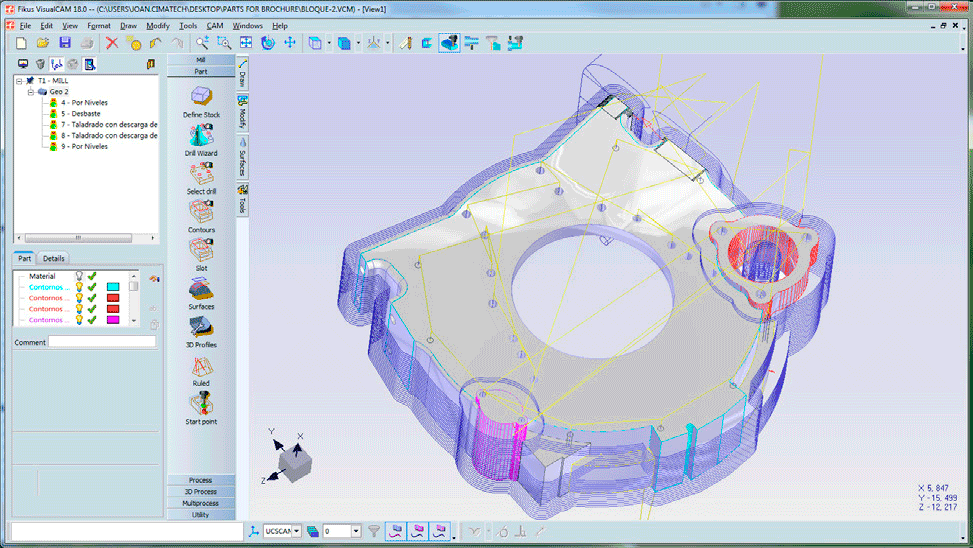

Metalcam releases a new Fikus Visualcam version to consolidate this CAD/CAM solution for workshop floor in a World reference position. In order to keep being acknowledged for its easy to use capabilities and its high productivity ratio, it is necessary to maintain a big and permanent effort in innovation, improving all the functionalities to become, everyday faster, easier to use and more efficient.

The new version consolidates this CAD/CAM solution for workshop floor in a World reference position

At Metalcam we work every day to maintain Fikus Visualcam as a leader solution and, for this reason we launch to the market the 18th version of our successful workshop floor CAD/CAM software.

New Fikus18 release