Neuheiten und Verbesserungen in Fikus.st 19

Schneller, zuverlässiger, mehr Funktionen und Funktionalitäten

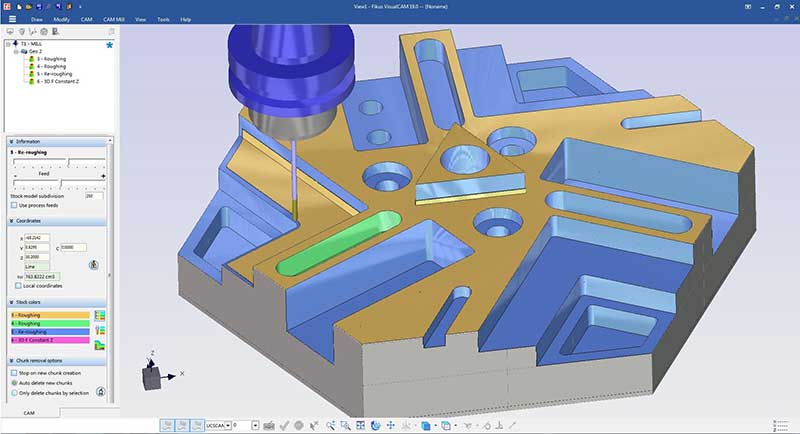

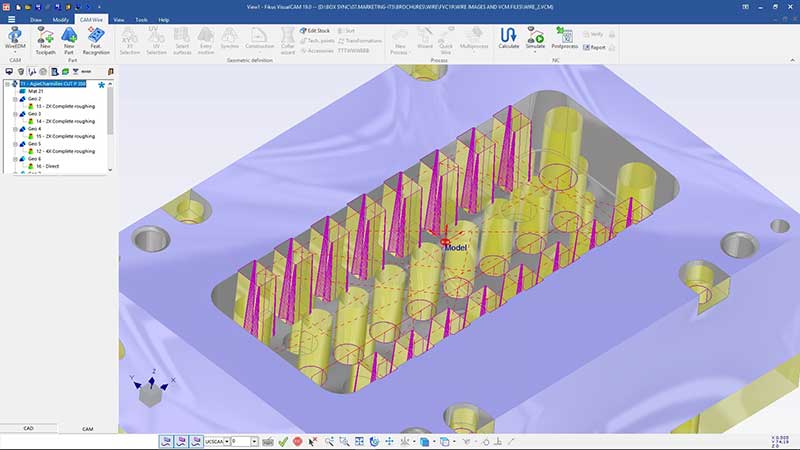

Metalcam bringt die neue Version von Fikus.st auf den Markt, die mehrere Verbesserungen und neue Funktionen enthält, um den Benutzern schnellere, robustere und erweiterte Funktionen und Funktionen zu bieten, die ihnen die neuesten Marktentwicklungen in Arbeitsprozessen zur Verfügung stellen und es ihnen ermöglichen, neue Geschäftsmöglichkeiten zu erschließen und neue Produktivitätsstufen zu erreichen.

Mehr Agilität bei der Nutzung

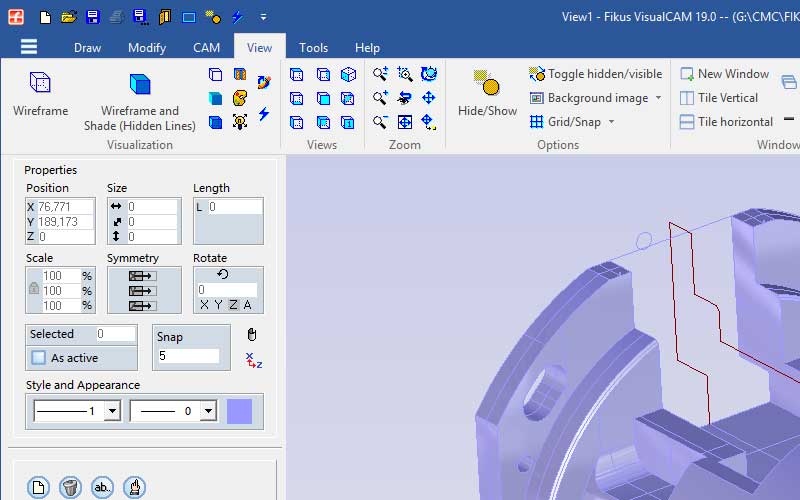

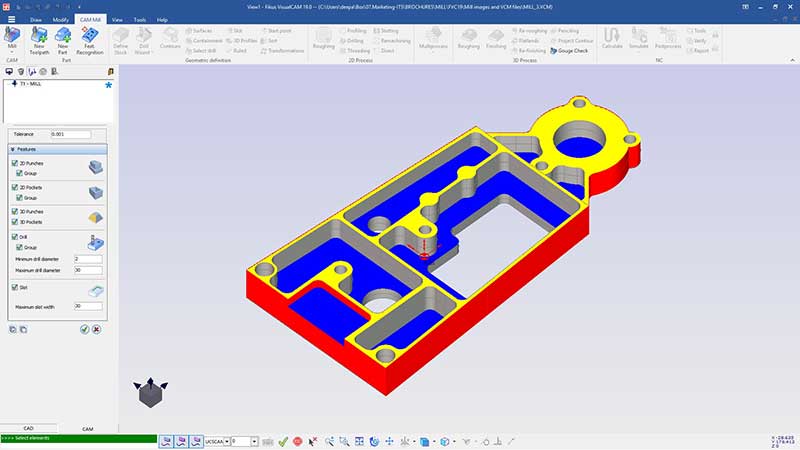

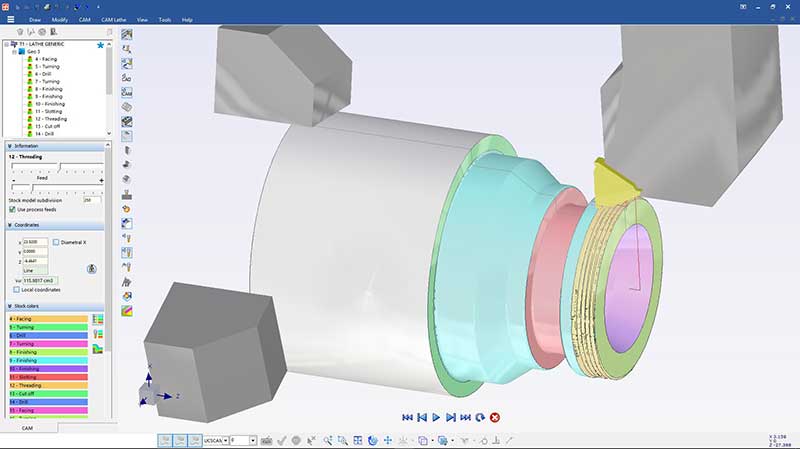

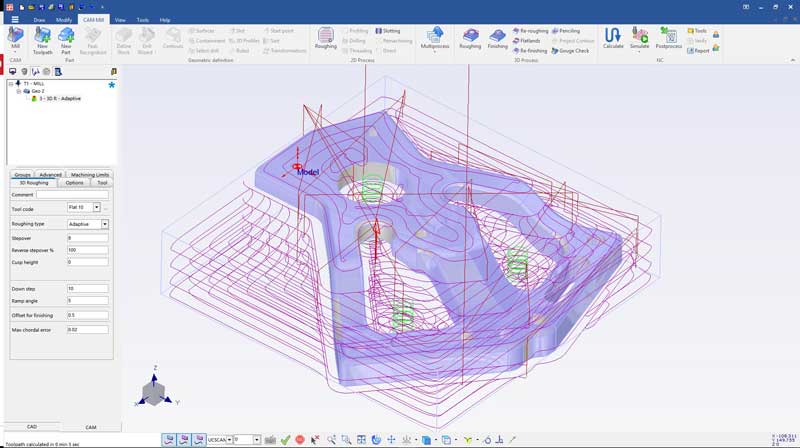

Viele der Verbesserungen und Neuerungen, die in der Benutzeroberfläche eingeführt wurden, zielen darauf ab, die Arbeitsgeschwindigkeit zu erhöhen, mit einem verbesserten System von Grafiken und neuen Symbolen, die Schritte für den Abschluss der Arbeit sparen.

Neue Icons und neue Distributionen zur Beschleunigung der Arbeit

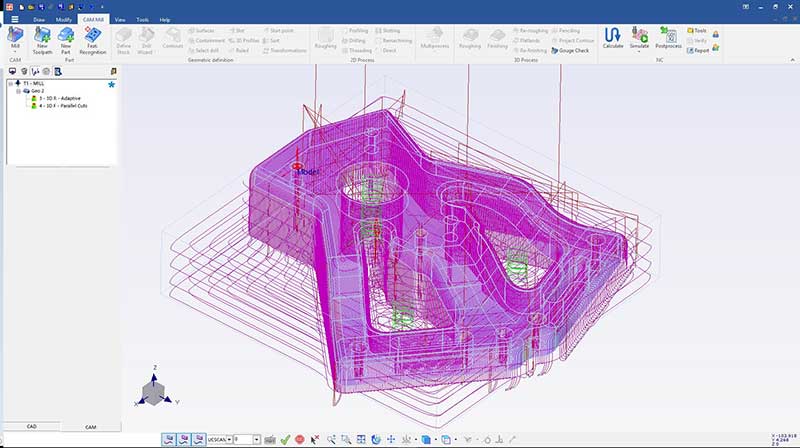

Die mit dieser Version von Fikus.st eingeführten neuen Funktionen und Verbesserungen betreffen den gesamten Prozess, vom Budget über das Design bis hin zur Endproduktion und in allen Technologien.

Agiler mit neuen Funktionen, die effizienter zusammengefasst werden.