The Wire EDM module of FikusPlus 20 has also developed significant improvements that affect almost all the working processes, such as Surface Selection, automatic Feature Recognition, or the level of work automation.

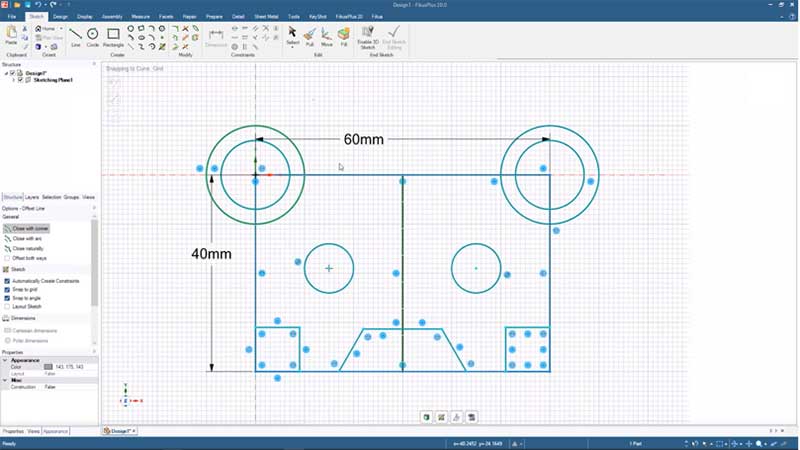

Now, the steps required to go from a geometry-based strategy to a phased strategy have also been reduced and can now be done automatically with a single mouse click.

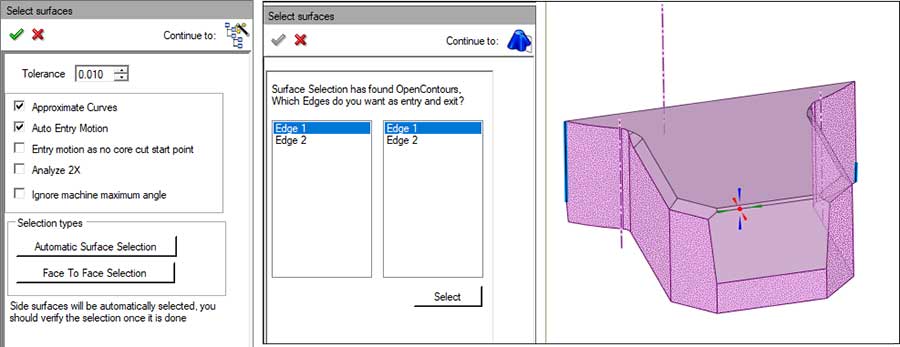

Improvements in surfaces selection

The Surface Selection proposes to the user the tangent surfaces in a selection and has a new function that detects the surface contours that define the open contours. These new functions help the user to reduce time and improve the quality of programming in open and closed contours.

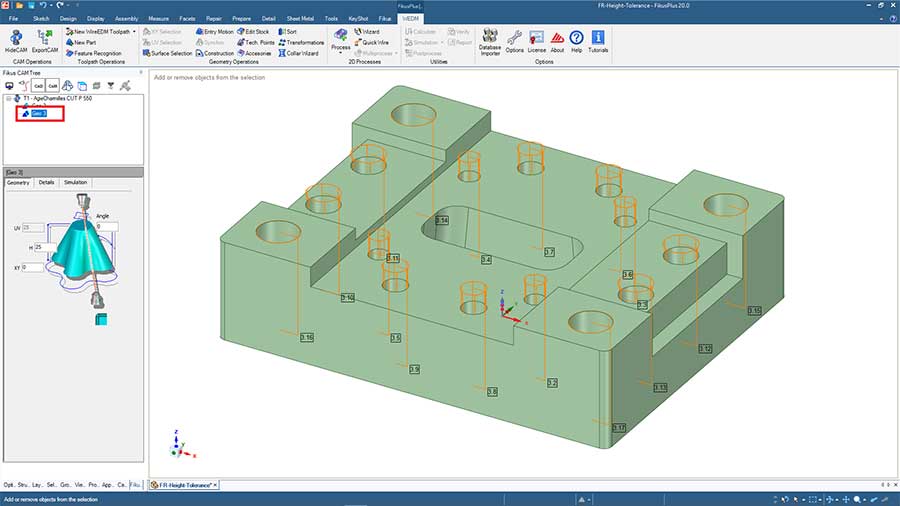

Optimized Feature Recognition

In the Feature Recognition function, a new method of automatic cylinder grouping and selection has been implemented, either by diameter or by height. This new functionality is very useful in geometries with multiple cylinders of different heights and diameters when applying the same cutting conditions to the whole piece.

Automation modules

Optionally, FikusPlus offers to the users the most advanced Automation Modules that increase productivity, reduce errors and allow the full control of the wire machining process by the users:

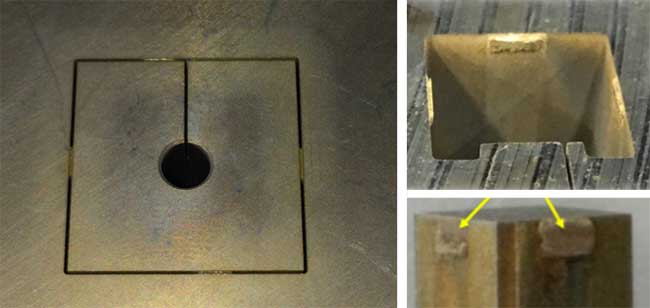

- ASM - Automatic Slug Management (Slug Extractor) is a new option to remove the slugs automatically, as soon as the roughing cut is over

- ASW - Automatic Slug Welding is a new function that we can use as an alternative to the conventional remnant cut

- AB - Alignment Basic Automatic Part Alignment Macros to setup the part position in XY plane using the wire

- A3D - Alignment 3D Automatic Part Alignment Macros to setup the part position in 3D space using touch probe

- AR - Renishaw Automatic Part Leveling Macros to setup the part position in XY & 3D space using Renishaw probe