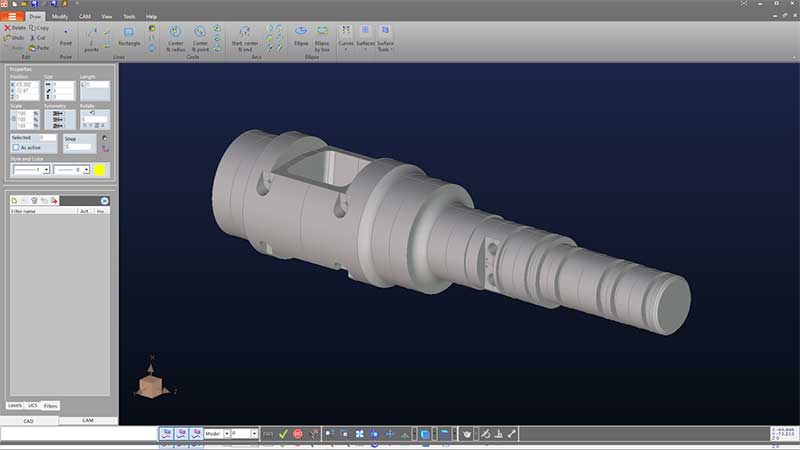

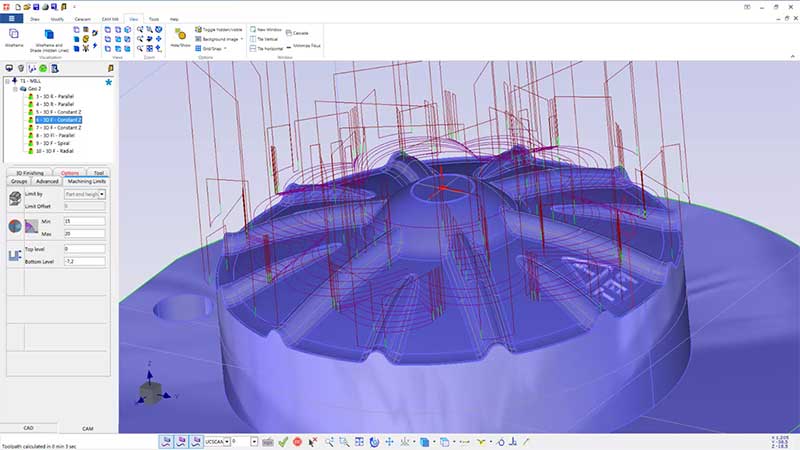

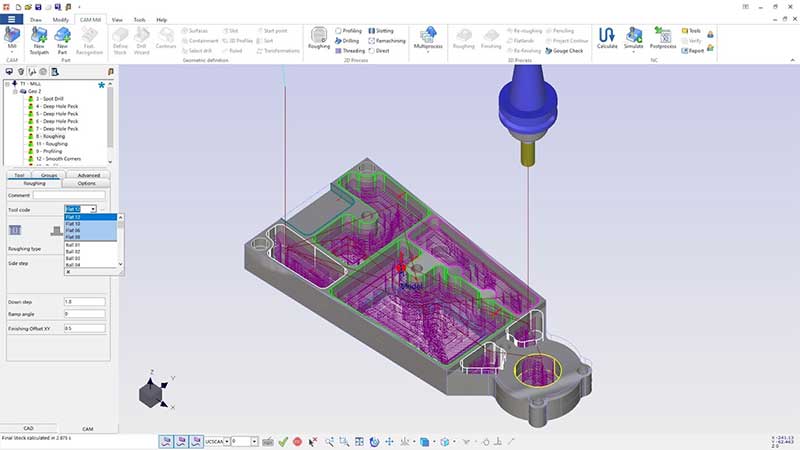

New FikusSt 20: The CAD/CAM developed for your shop floor, designed for you

Metalcam launches the new version of FikusSt, the CAD/CAM software specially developed for the workshop, which offers industry all the functionalities, speed and agility to access new business possibilities and reach new levels of productivity.

Streamlined and customizable

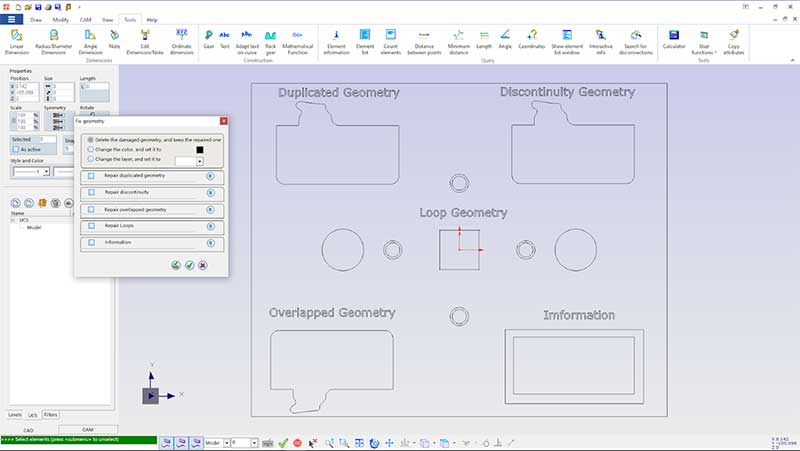

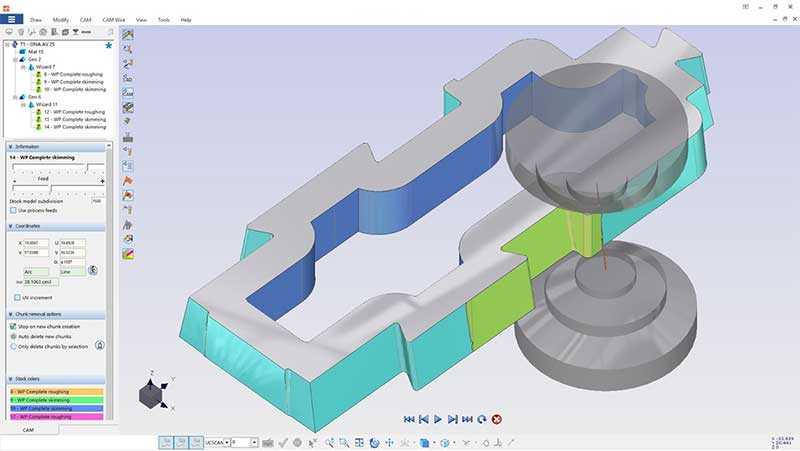

FikusSt 20, is a step forward in productivity compared to the previous version, with significant improvements in calculation algorithms, workflow organization, automation or rationalization of the steps necessary to execute design and manufacturing tasks. Fikus now takes 10% less time to open files.

It is now possible to insert several files into any Fikus function, simply by dragging and dropping them with the "shift" button, so it is possible to work with several geometries simultaneously. The way to exit functions has also been improved; in addition to the cancel button, there are now buttons on the bottom or top bar, especially useful with touch screens.

Another aspect that has been improved is the capability of customisation to easily adapt it to users' preferences, with a more efficient system for managing colour combination preferences or the inclusion of the dark-mode option.

FikusSt 20, developed for the shop floor