Complete solution

FikusWorks is available as a comprehensive CAD/CAM solution, in three different configurations to suit your needs:

- SolidWorks CAD (parts-only) + Wire EDM CAM

- SolidWorks CAD (Parts & Assembly) + Wire EDM CAM

- SolidWorks CAD (Parts & Assembly & Drawings) + Wire EDM CAM

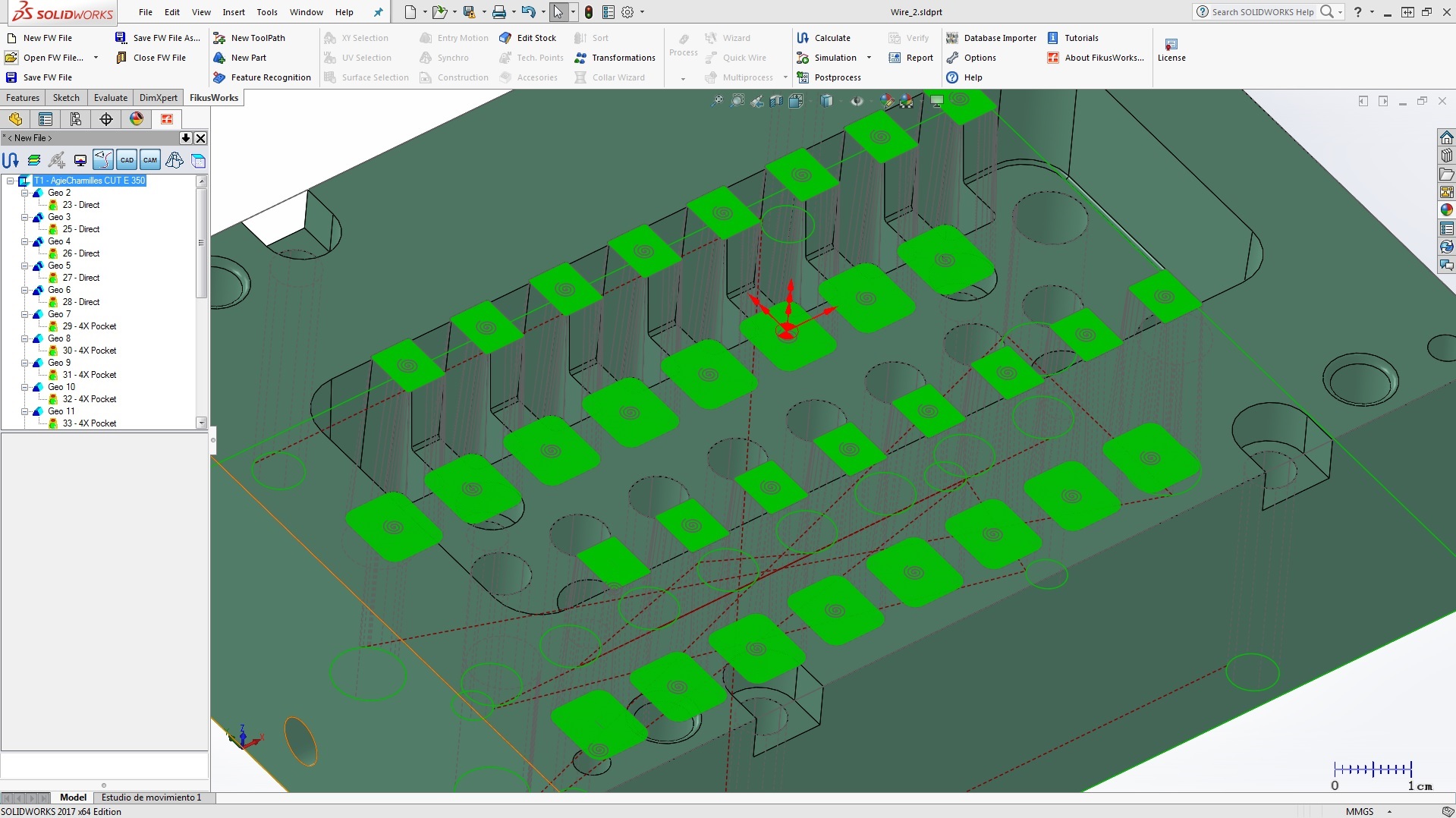

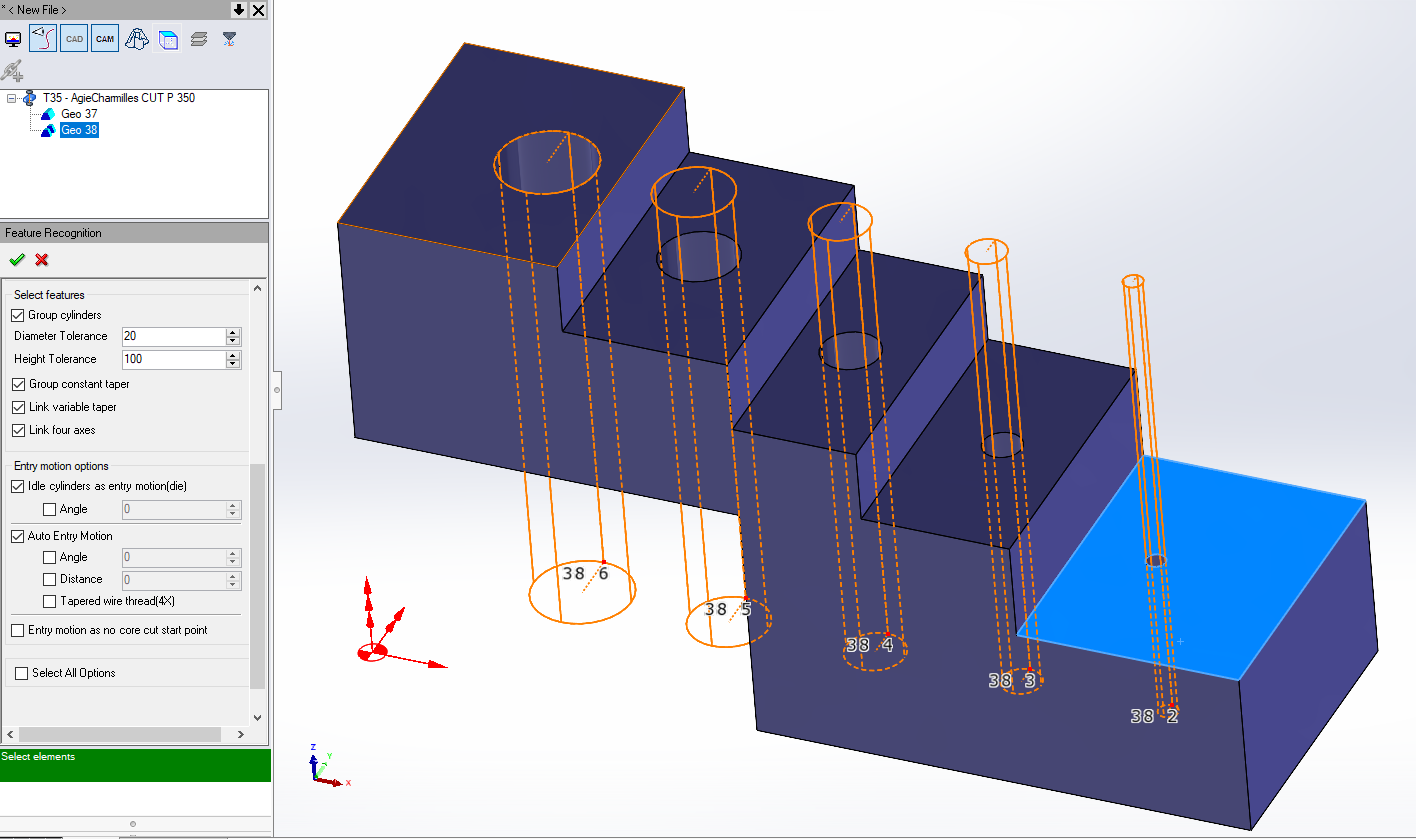

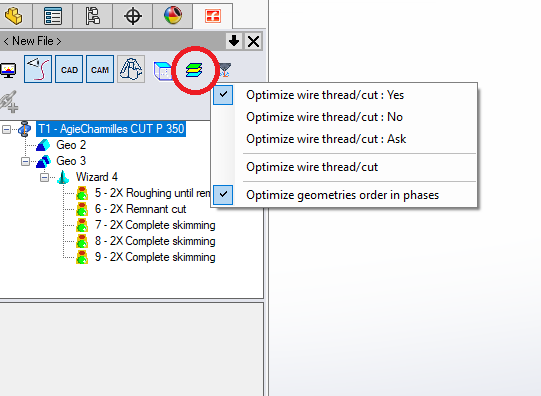

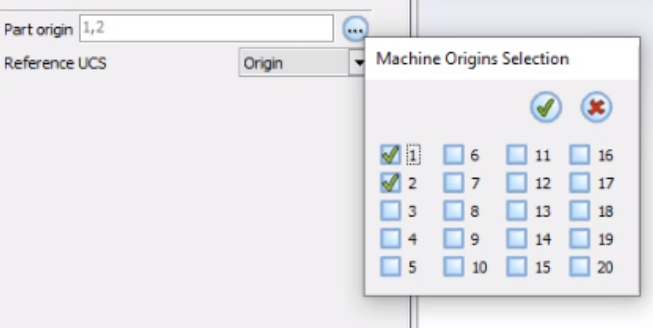

All the tools available in FikusWorks can significantly improve productivity and manufacturing time, such as specific machining wizards for different machines, templates, customizable databases or automatic technological points, which are available to make your work easier and more productive.

Machine technologies from manufacturers Like Accutex, ActSpark, GF Machining Solutions, Chmer, Fanuc, Hitachi, Joemars, Makino, Mitsubishi, ONA EDM and Sodick are implemented in FikusWorks with optimized technological tables and postprocessors. The programming wizards help to create the cutting sequence step-by-step and control all the machining parameters. Thus the Expert Knowledge helps to complete the programming process easily and efficiently.

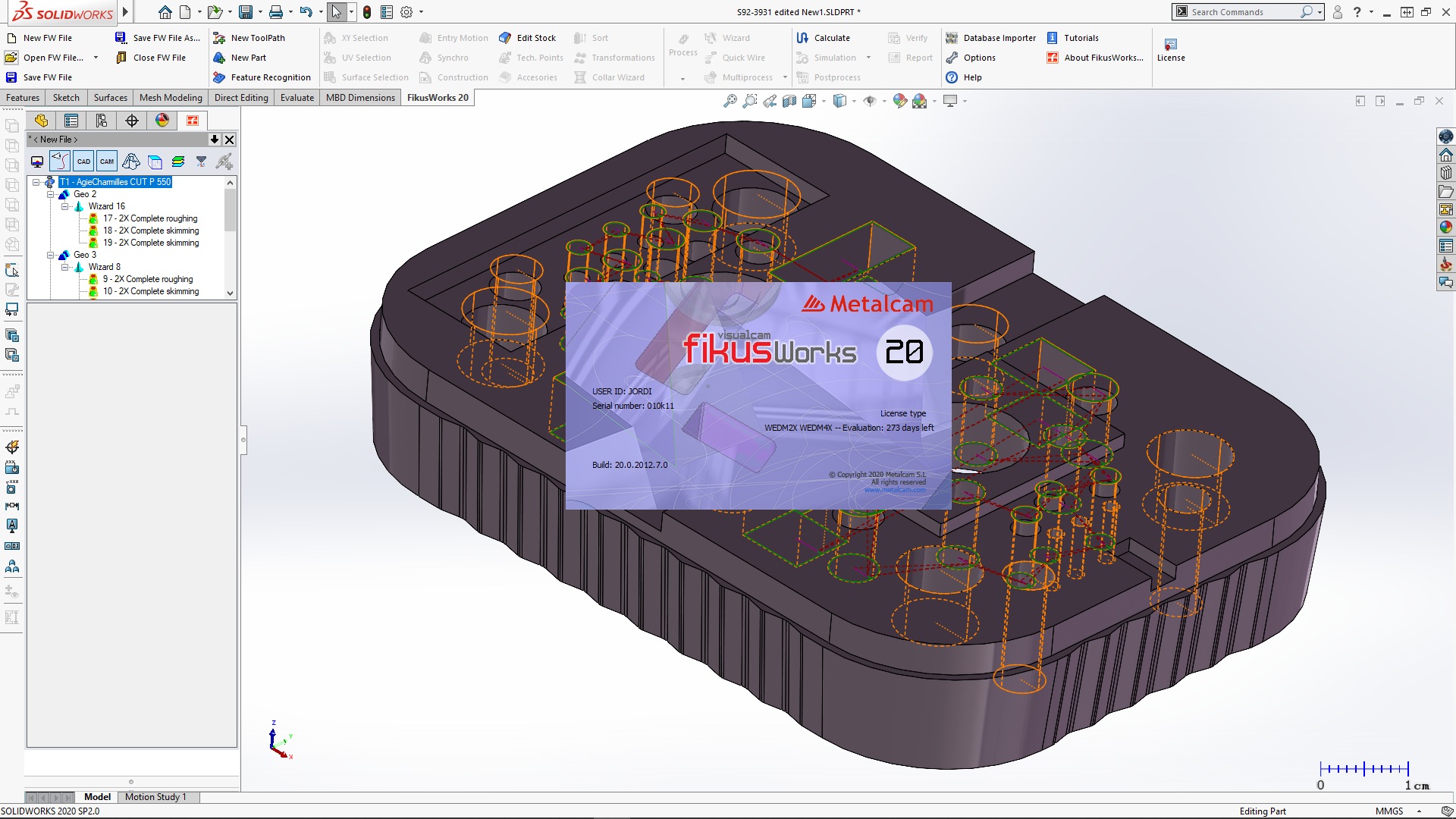

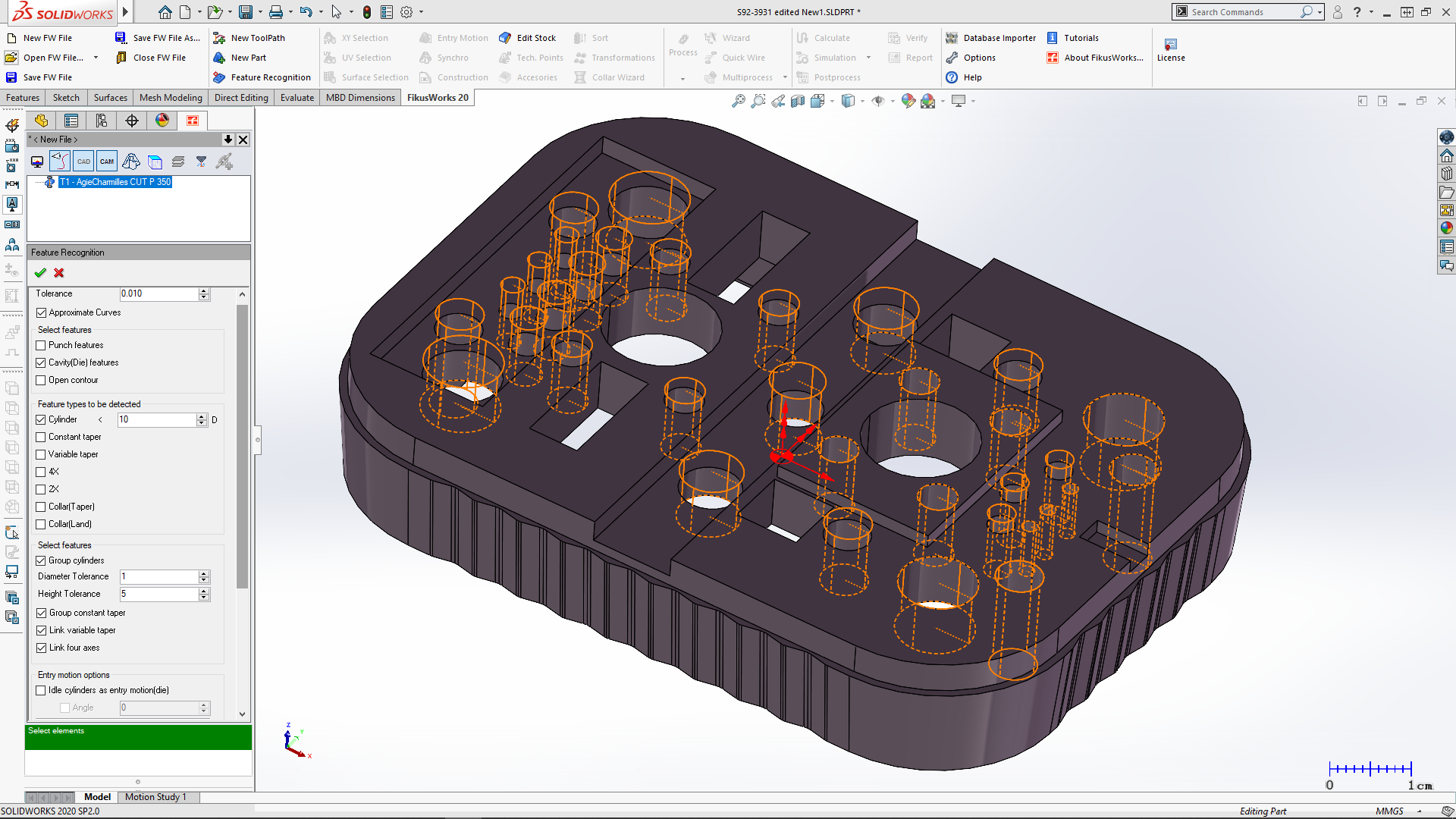

Fully integrated add-in

FikusWorks 20 is also available as an add-in to integrate the best wire EDM CAM solution on the market into your Solidworks platform and start programming the machining immediately.

Once you have finished your CAD tasks, you can directly open the FikusWorks tab in the SolidWorks main menu and start working with the intuitive, easy to use and efficient FikusWorks CAM solution for wire EDM.