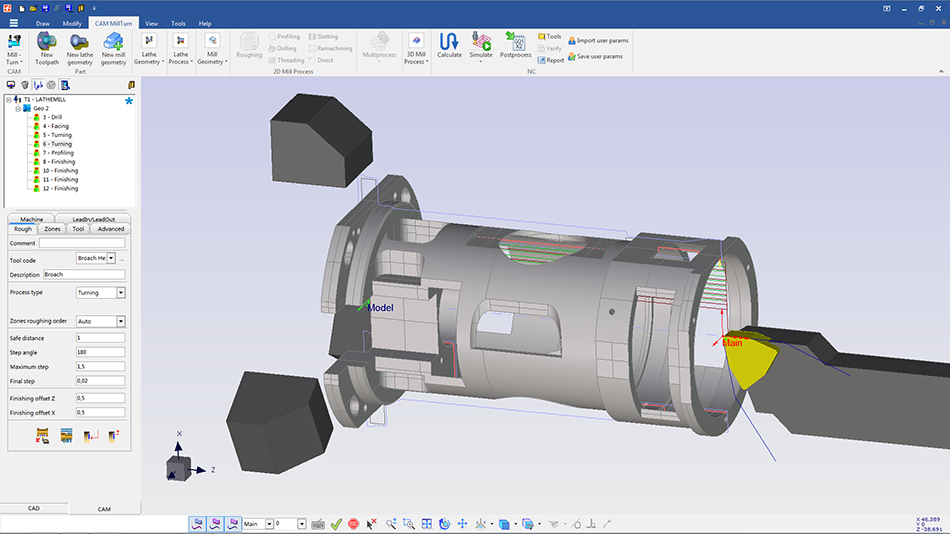

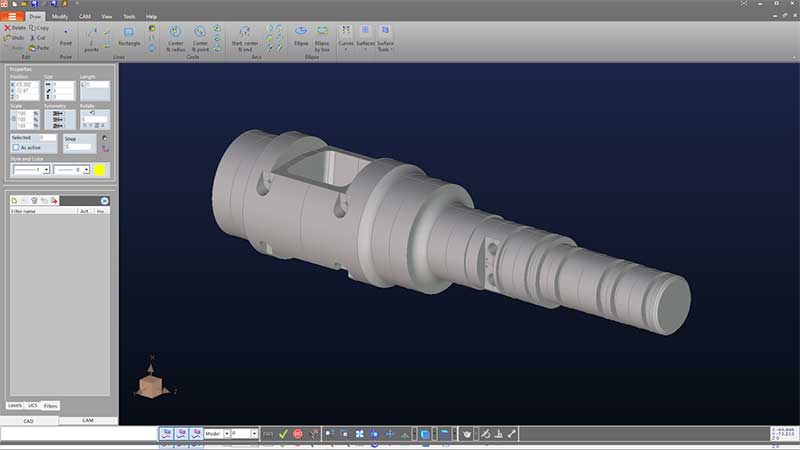

Fikus ST a complete CAD/CAM developed for the shop floor

The CAD/CAM for the shop floor that gets all the performance out of your machines

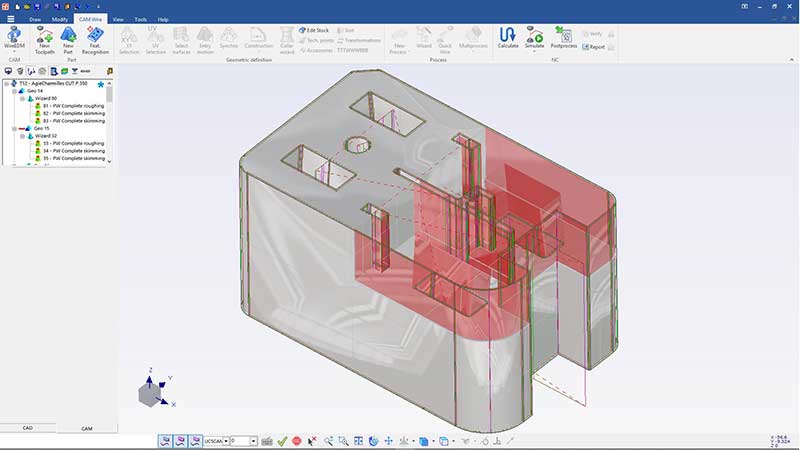

Fikus ST is the Metalcam`s recognized software for the shop floor. offers a complete and efficient solution, designed to easily and quickly produce parts, using a wide range of innovative software tools to reduce programming time and increase productivity.

A versatile, productive and easy-to-use CAD/CAM that gets the most out of machine tools thanks to specific machining wizards and postprocessors for the vast majority of machines on the market.

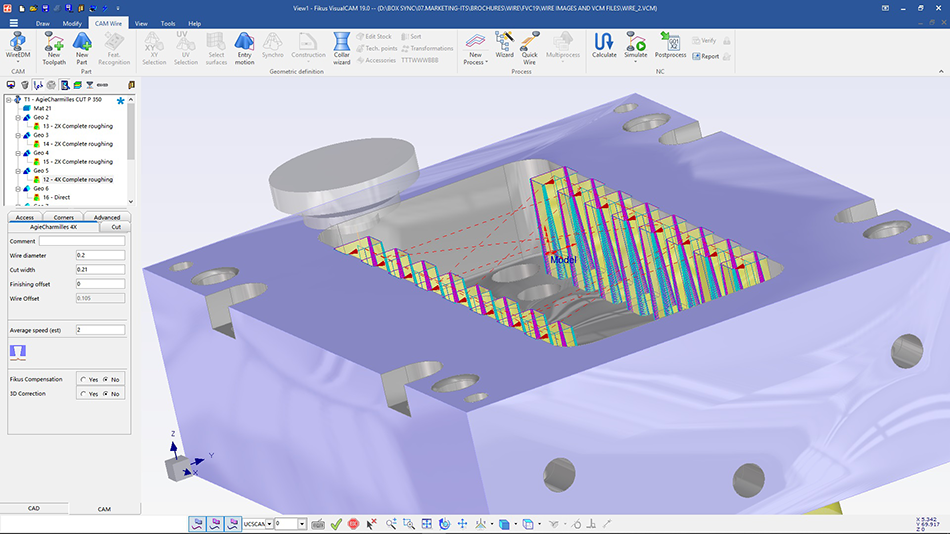

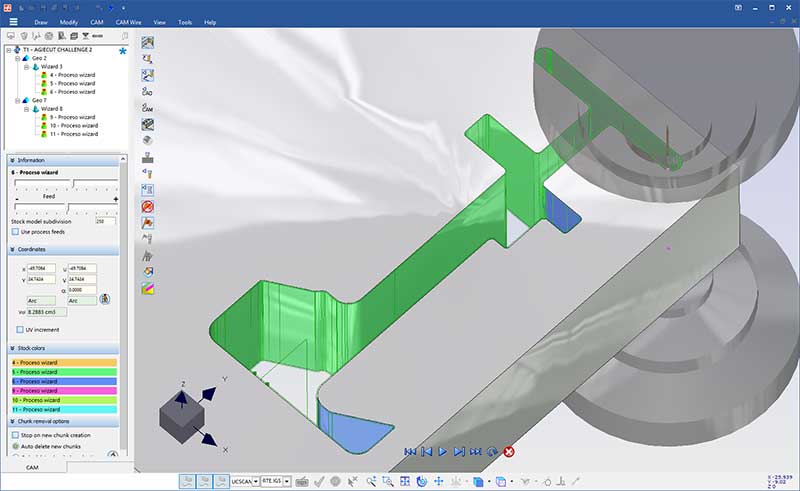

Working environment simulating wire EDM toolpaths

Fikus ST key features

- Reduce time-to-market and work hours drastically.

- Shorten geometry construction and part definition efforts.

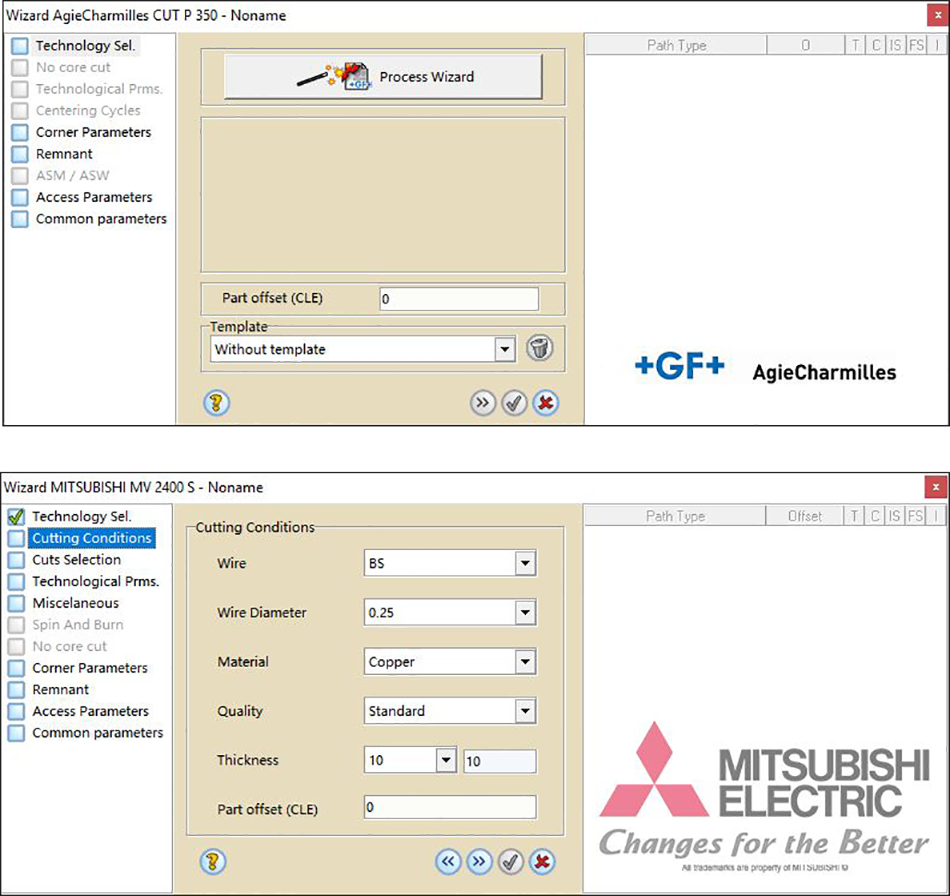

- Machine specific Wizard and technological databases optimizing production time and quality.

- Automatic Feature Recognition that recognizes the areas to be machined and programs them automatically.

- Allows to program your machining operations in only three steps: select the geometry, define processes or parameters, and calculate.

- The CAM manager guides you easily and safely through the logical working process.

- Advanced toolpath algorithms calculation.

- Advanced functions in all machining technologies: rotary axis on wire EDM, adaptive and trochoidal roughing on milling cutters...

New screen mode "dark-mode"

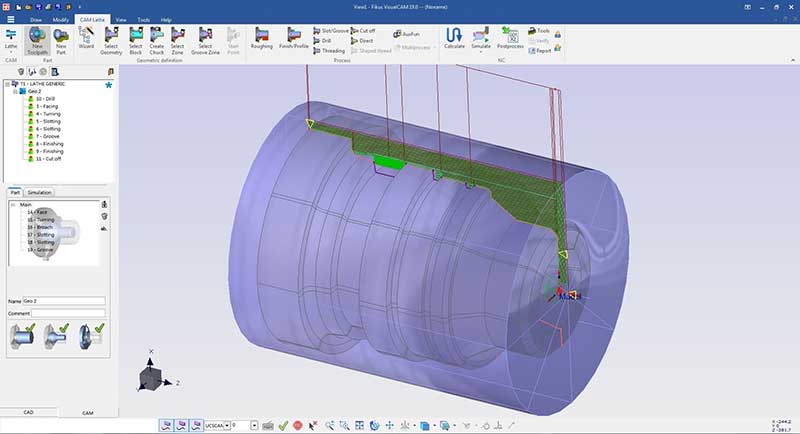

Optimal CNC programs for your machine in just three steps

Fikus ST is an intuitive solution, very easy to use and learn, and highly automated. It is only necessary to select the geometry, define the processes or parameters, and calculate.

It has a CAM manager that guides the user through the logical programming process, from the definition of the part to the creation, calculation and simulation of each machining process to achieve easily and error-free the most efficient machining.

Efficient technological wizards assist the user in this process ensuring optimal machining processes, adapted to the characteristics of each machine and type of work.

Fikust offers a realistic 3D machining simulator, specially developed for verification, collision detection and complex machining simulation.

Wire EDM cutting simulation

The profitability of automation

Fikus ST includes the Automatic Feature Recognition function, that detects the different areas to be machined and programs them automatically, generating efficient processes.

The Drill Wizard detects all holes, grouping them according to their characteristics, and programs their machining automatically and efficiently.

As Fikus ST solutions include customized technology tables for the different machines on the market, generates machine-specific CNC programs and no on-machine modifications are required.

Templates for an optimal machining

If you have already defined and tested your best machining strategy for a part, you can save it as a template and use it later for similar parts. You will save time and will avoid mistakes.

Lathe CAM manager

Productive CAD/CAM shop floor software that optimizes the performance of your machines

Productive CAD/CAM shop floor software that optimizes the performance of your machines