Advantages of the adaptive roughing

Adaptive machining is an advanced machining technique used by industry primarily in the high-performance machining of metal parts.

This type of machining is part of the roughing operations (also known as adaptive roughing or trochoidal roughing) and consists of the material roughing operation, reducing production times and improving efficiency. This is achieved through the use of special tool paths and machining strategies that seek to maintain a constant cutting load and the use of smooth changes in cutting direction.

High-performance machining

One of the key features of adaptive machining is its ability to remove large volumes of material in a single pass, thus reducing machining time. Reducing machining time means increased productivity and profitability. Adaptive roughing can reduce times by up to 50% compared to a similar process without the adaptive technique.

Extends the service life of machine tools

Adaptive machining uses advanced algorithms to calculate the most efficient toolpaths, taking into account factors such as part geometry, material to be machined, machine capabilities and cutting conditions. These algorithms help optimize cutting speed, depth of cut and cutting direction, thus maximizing productivity and tool life.

Smooth transition paths with a constant angle and depth of attack allow to extends the service life of machine tools. In addition, adaptive roughing generates high-quality surfaces and reduces chip formation and vibrations during the process. Extending the service life of our machine tools is a considerable benefit, as cutting tools account for around 10% of workshop costs; extending their service life and thus reducing maintenance and refurbishment costs are of great benefit to machining shop floors.

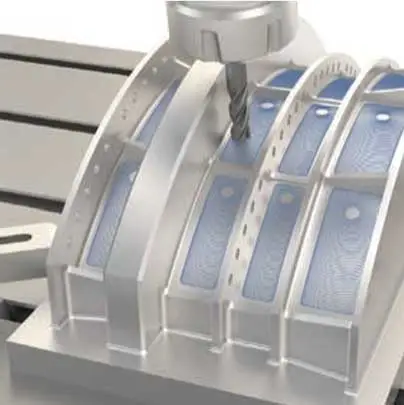

The Fikus trochoidal roughing

The Fikus adaptive roughing extends cutting tool life by smooth entry into the material, utilizing the full length of the cutting edge and generating smooth transitions paths with constant angle and depth of attack. Fikus trochoidal roughing allows improvements of up to 60% in roughing strategies.

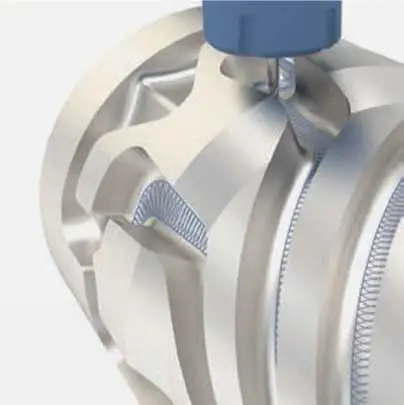

4 axis adaptive machining

5 axis adaptive roughing