Fikus ST 25: more powerful, faster, reliable, and efficient.

Launching of Fikus ST 25

Barcelona, October 2025

Metalcam S.L is pleased to announce the release of Fikus ST 25, an updated version of their renowned CAM solution designed to optimize shop-floor manufacturing processes. Fikus ST 25 represents a significant leap forward in design and machining software, delivering substantial improvements in performance, efficiency, and usability, making it an ideal choice for professionals seeking excellence and productivity.

This new version has been developed to provide a more powerful, faster, reliable, and efficient solution. The application’s infrastructure has been modernized with updated libraries and code migrated to a 64-bit architecture, enhancing security, ensuring compatibility with modern operating systems, and increasing overall performance and stability. Users will experience greater agility, with calculations up to 60% faster in certain processes and smoother, quicker stock simulations, offering more fluid tool-path visualization

Fikus ST 25, more powerful, faster, reliable, and efficient, increase overall performance and stability

Maximizing productivity

Fikus ST 25 introduces key technological innovations to maximize productivity:

- Twin-wire Technology: Now supports UNIQUA’s Twin-wire technology on the AgieCharmilles Cut X machine, using two wires to increase precision, reduce machining time, cut thicker materials, and handle complex shapes with greater stability.

- Trochoidal Roughing for Milling: A new trochoidal roughing strategy removes more material in less time, significantly reducing machining time and extending tool life.

The new trochoidal roughing strategy reduce machining time and extend tool life

Improved user-experience

The version also integrates major user-experience enhancements:

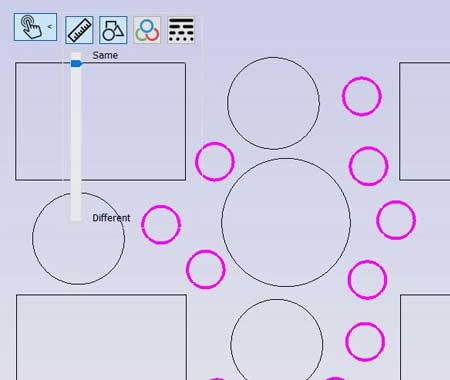

- Enhanced Feature Recognition: Improved to handle parts combining open and closed contours in Wire technology, and with smarter milling operations.

- New Selection Wizard: Simplifies the filtering of wire geometries by type.

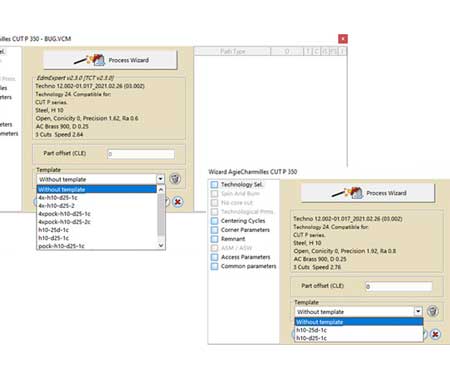

- Automatic Template Generation: Automatically creates templates based on the user’s typical jobs—up to 50 different templates—with a new wizard to streamline creation and loading.

- Redesigned User Interface: A fresh, clean, and modern design that enables work with fewer clicks, including a new start screen, updated icons, and adaptive ribbons. A “red dot” highlights new or updated functions.

- Automatic Scrap Management (ASM) for UNIQUA: A system that, once the part is fully cut, uses a vacuum-equipped movable arm to collect it and place it in a dedicated container, allowing machining to continue without interruption.

- User Registration Process: A new security step for license acceptance and registration, privacy policy, and EULA—even if the computer is offline.

- 3DConnexion SpaceMouse Support: Now available as an optional input device.

- Improved Reports: UV coordinates of conical threading points are now included.

New and more agile system for selecting geometry features

Efficient and Productive Solutions

Fikus ST is a complete and efficient CAD/CAM solution for the shopfloor, designed to produce parts quickly and easily, reducing programming time and increasing productivity. Its intuitive, highly automated environment—together with technology wizards and machine-specific post-processors—delivers optimized CNC programs for a wide range of technologies, including Wire EDM, 2D/2.5D/3D/4D y 3+2D Milling, and Turning. Fikus ST can also import data from other CAD systems in formats such as IGES, SolidWorks, DWG, DXF, STEP, Parasolid, and Cimatron.

Metalcam reaffirms its commitment to continuous innovation and high-quality technical support, ensuring that Fikus ST 25 remains an essential tool for meeting today’s industrial challenges.

Improved automatic template generation and loading system that adapts to each type of job

Share this article

Download here the What's New brochure

Click here or on the image to read, download or print the PDF file of the What's New in Fikus ST 25 brochure.

Boosting Efficiency and Precision in Industrial Manufacturing

Boosting Efficiency and Precision in Industrial Manufacturing