New solutions to increase automation with Agie Charmilles WIRE CUT machines

Discover a new level of automation in wire EDM

Metalcam’s and GFMS’s research and development departments have been working in cooperation to offer a new series of modules for the AgieCharmilles CUT and VISION machines to increase automation and control in Wire EDM machining. With ACcam.easy and Fikus Visualcam you will have complete control of the new features of the machine with its direct programming. Using the software, you increase productivity with higher levels of automation.

Automation modules

- ASM - Automatic Slug Management (Slug Extractor) is a new option to remove the slugs automatically, as soon as the roughing cut is over

- ASW - Automatic Slug Welding is a new function that we can use as an alternative to the conventional remnant cut

- AB - Alignment Basic Automatic Part Alignment Macros to setup the part position in XY plane using the wire

- A3D - Alignment 3D Automatic Part Alignment Macros to setup the part position in 3D space using touch probe

- AR - Renishaw Automatic Part Leveling Macros to setup the part position in XY & 3D space using Renishaw probe

- TBI - Turn and burn Indexed Positional (indexing) cutting using Rotary attachment. Also known as Turn-then-burn. Programing like any other EDM operation but moving the rotary axis between the operations.

A new icon called Accessories will let you define where is the picking point for the Slug (ASM).

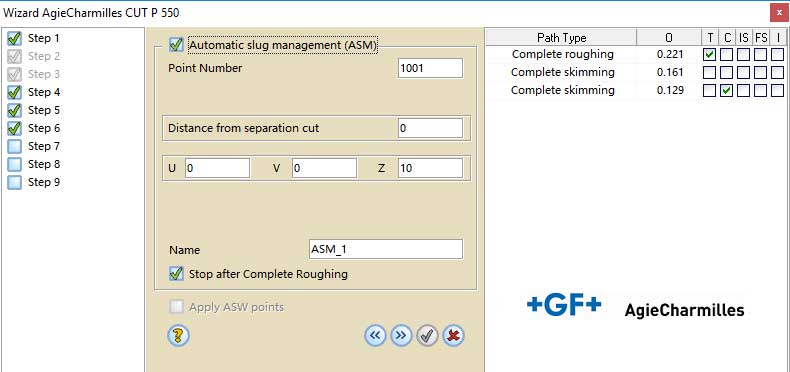

ASM - Automatic Slug Management

The Automatic Slug Management (or Slug Extractor) is a new option that allow to automatically remove the slugs by the time the roughing job is done. The remnant is extracted from the top of the workpiece and placed in a slug holder (repository). With this new automation feature, manual intervention and total processing time will be reduced boosting productivity.

Wizard for the new ASM module

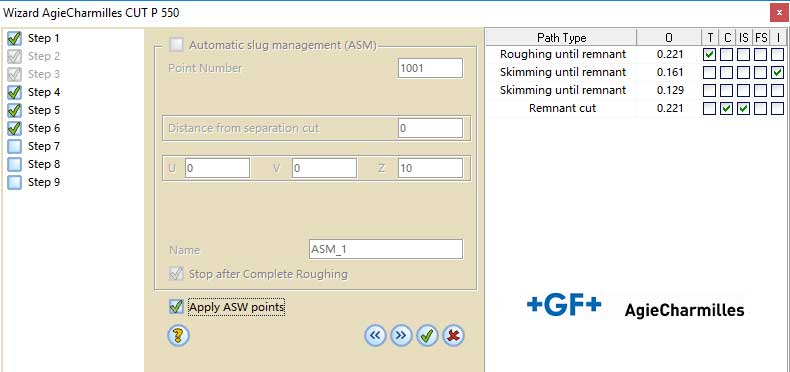

ASW - Automatic Slug Welding

The automatic Slug Welding is a new function that will allow you to choose a different way to hold the part and extract the slug. You can use it like an alternative to the conventional remnant cut. It fixes the piece with the same wire used for cutting. A special large pulse will melt the wire in the upper section of the Workpiece. The higher the pulse, the higher deposit height will be obtained.

The Die can be fixed anywhere on the geometric path during its Main CUT. To remove the core slug at the end of the main cut a simple knock out will do it. Users can use ASW instead of the typical Remnant cut to achieve better surface quality.

With the Automatic Slug Welding function you will be reducing processing time up to 10% and manual intervention up to 90%.

Wizard for the new ASW module

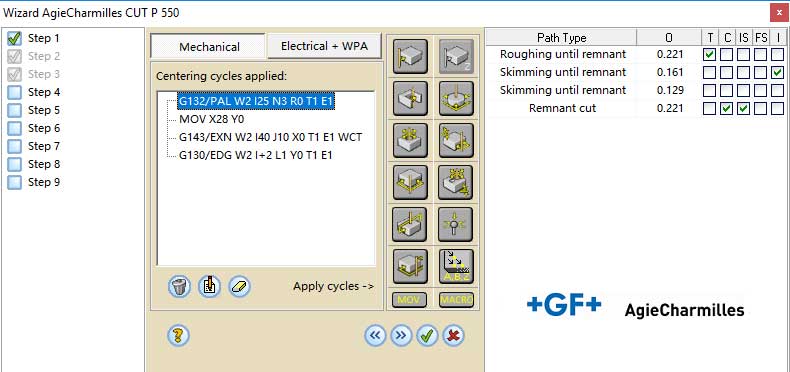

AB - Alignment Basic

To guarantee the correct position of the part is vital to get a completely accurate output from your machining. With Automatic Part Alignment Macros, you can setup the part position in XY plane using the wire helping the operator to correct the coordinate system from the reference coordinate system.

This 2D probing routine can be used to identify the program starting point and determine part feature locations and sizes.

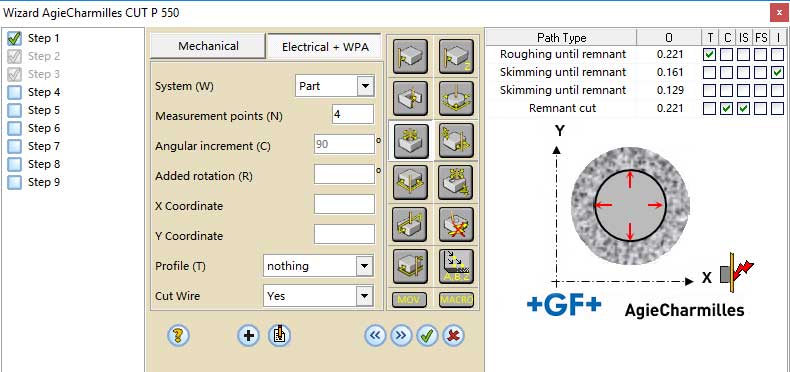

A3D - Alignment 3D

Advanced Control and Automation. To secure precision in large multiple die-tools use the Automatic Part Alignment Macros to setup the part position in 3D space using a touching probe. This function will correct possible misalignments; The cycle consists in touching the part in z level in 3 points to identify the possible misalignment and find the new angle of the plane. With the A3D Setup module an outstanding ±2 μm probing accuracy can be achieved.

Wizard for the new A3D module

AR - Renishaw

With AR probing cycles you can automatically establish workpiece and electrode alignment and size to reset the coordinate system and calculate 2D or 3D work offsets. Automatic Part Alignment Macros to setup the part position in XY & 3D space using a Renishaw probe.

Wizard for the new AR module

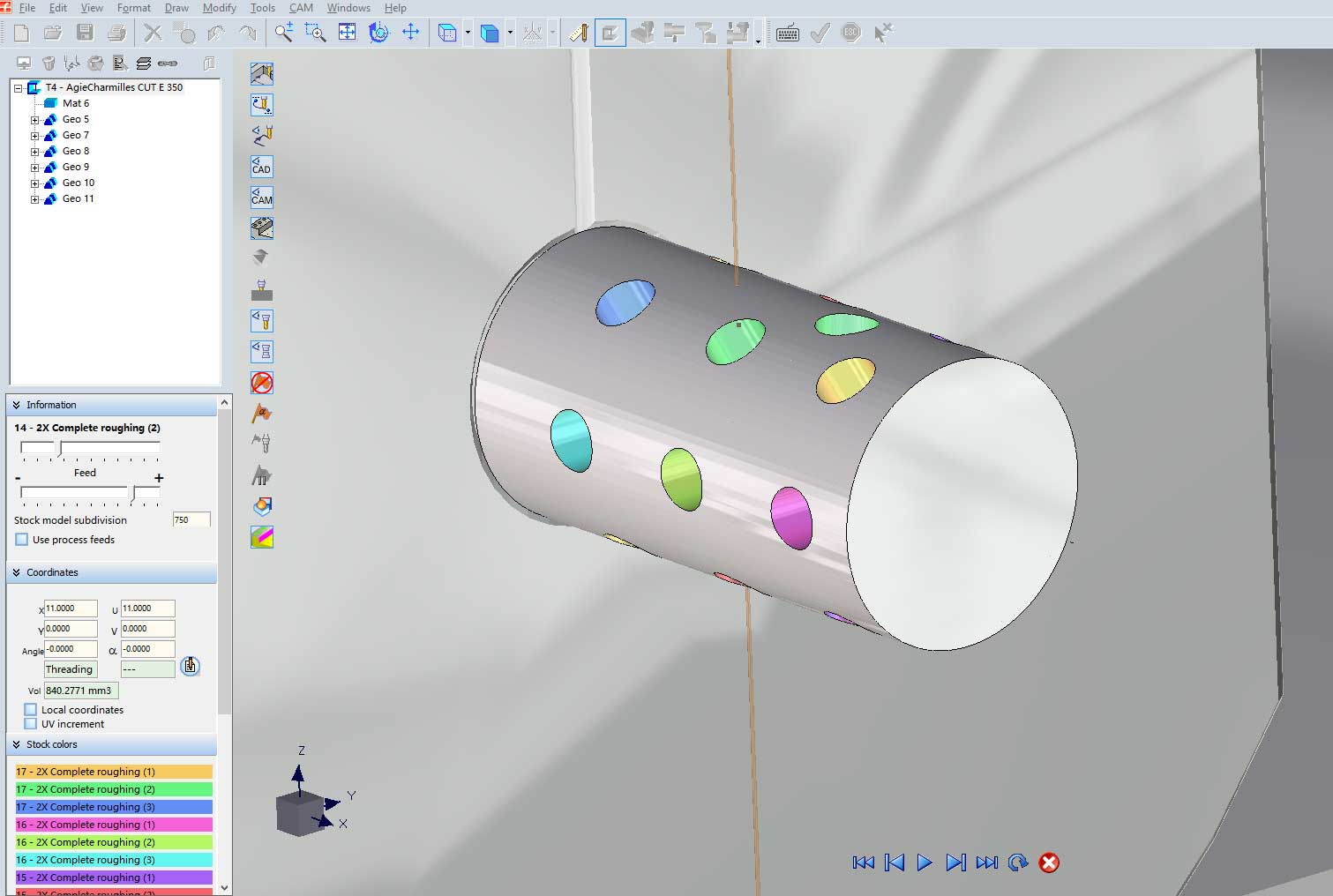

TBI - Turn and burn Indexed

Upgrade your Wire EDM machine’s possibilities with the new Turn and Burn module. This new module allows positional (indexing) cutting using Rotary attachment. Also known as Turn-then-burn. Programing like any other EDM operation but moving the rotary axis between the operations.

Compared to traditional lathe-turning operations that require multiple tool passes to remove material, with the new Turn and Burn module you will be able to erode all material that must be cut with each rough and finish pass. Moreover, instead of turning the stock on a lathe, send it out for heat treating (which can distort the machined part), and then put it on the machine once again for additional machining or grinding operations to bring the component to final size, the Wire EDM Turn and Burn can accurately turn hardened stock in one setting, enhancing accuracy and reducing the overall manufacturing cost.

Turn & Burn Indexed new module

Download here the PDF brochure

Click here or on the image to read, download or print the PDF file of our brochure.

Click here to access the brochures of all our products.

Complete range of advanced automatic processes developed in collaboration with +GF+ Machining Solutions

Complete range of advanced automatic processes developed in collaboration with +GF+ Machining Solutions